Bioplastic Created From Eggshells and Nutshells

Interview with Rania Elkalla

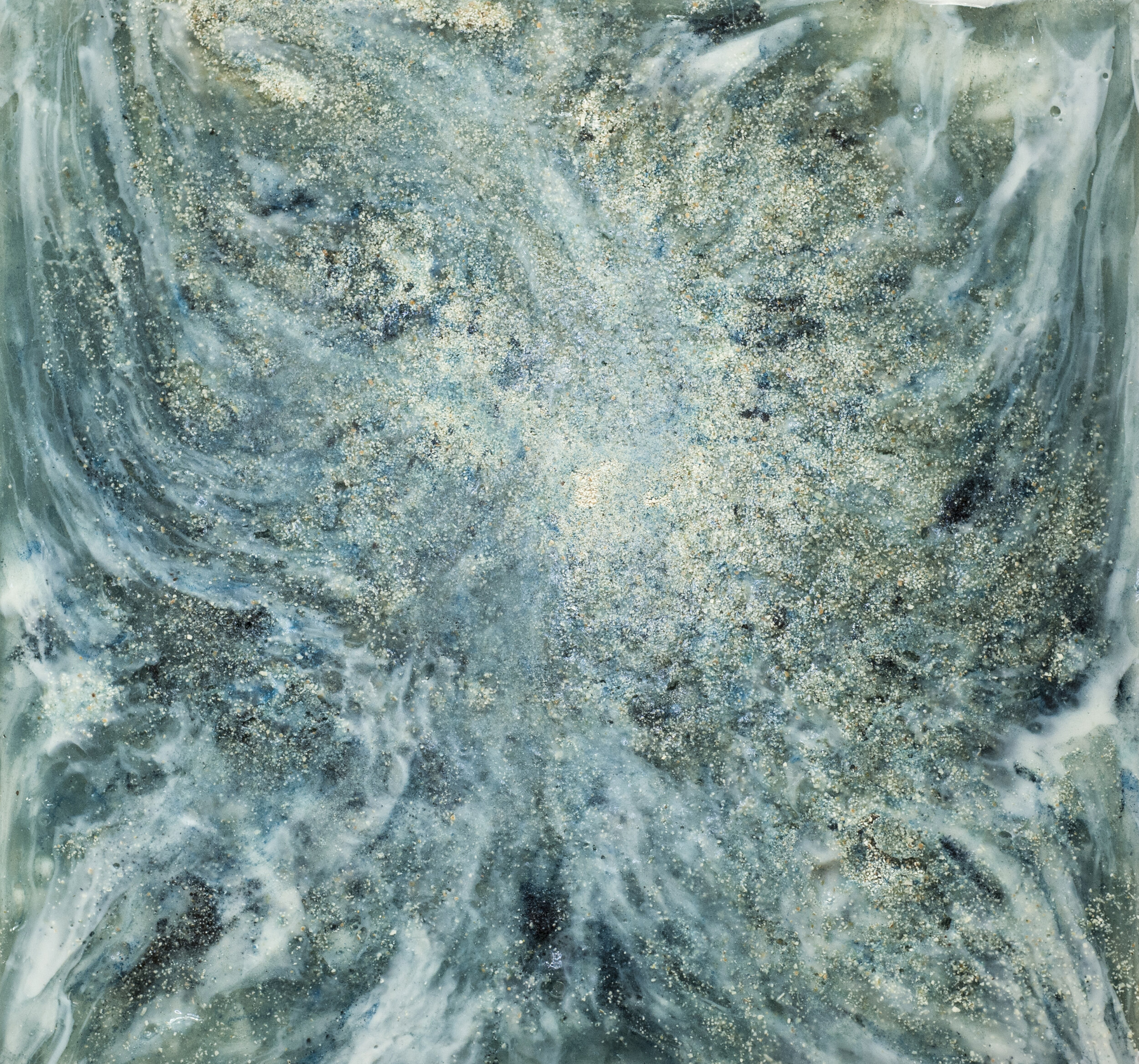

Shell Homage

Shell Homage Hangers by Rania Elkalla

In our current society, industrial and household waste are abundantly available, so designers and researchers have recognized the potential of using this waste to innovate new materials. With our current linear model of "take-make-dispose," we can witness the negative impacts of this economic system on the environment and society. We can no longer consider design as an activity that simply focuses on aesthetics and functionality. Still, with an urgent need for an efficient and cyclical approach, designers are hastily changing their relationship with materials and creative processes.

As argued by Seetal Solanki in Why Materials Matter, we are on the edge of a material revolution where designers could improve our relationship with the planet and change society for the better. Everyday materials have the incredible potential to provide solutions to some of the most urgent environmental and socio-economic issues facing our world today.

We spoke to product designer Rania Elkalla about her innovative and green award-winning project (2018/2019), Shell Homage.

Tell us about yourself. How did you become a material designer?

I’m an integrated designer with an educational background in product and graphic design, as well as experience in material science and production. I had an interest in materials from a very young age. I love feeling and touching tangible objects; for example, I would rather buy a magazine than read it online because I love the texture of the paper, the embossed elements on the cover, and the smell of the fresh print. From when I was a design student, I began to understand the integral role of materials in design and began collecting various materials for inspiration, like the net from cheese packaging or the mesh metal sheet used in filters.

I believe that good design is long-lasting and that every product should have a purpose and a function. I strive to challenge myself and the materials I use to create products that are eclectically designed but visually simplistic. When it comes to any design, function, and quality should be as important as ethical sourcing and production. I believe that all types of design are linked with one another, and a designer must be a flexible risk-taker who is able to merge different techniques.

I’m skilled in visual communication, branding, illustrating, designing 2D and 3D products, experimenting with materials, and merging different disciplines. I would describe my work as rich, vibrant, eclectic, and derived from various cultures and styles. My main aim is to keep on improving my skills and to present the best, most authentic version of myself through my work. Designers should always remember the word “FUN” that exists in Function. I tend to design things with humor and interaction with users.

What is the meaning of sustainability to you?

To me, sustainability means using non-toxic, sustainably produced, or recycled materials that have a lower environmental impact than synthetic materials. This should be paired with the use of energy-efficient manufacturing processes, and we should strive to build longer-lasting, better functioning products that need to be replaced less frequently. The product’s life cycle should be considered carefully; sustainable goods should be designed with recycling in mind, making it easy to disassemble so that its parts can be used to create new products. If this isn’t possible, the materials should come from renewable sources that can be composted when the product’s use has been exhausted.

What is the role of designers and researchers in sustainable initiatives?

“Sustainable development is the pathway to the future we want for all. It offers a framework to generate economic growth, achieve social justice, exercise environmental stewardship, and strengthen governance.”